This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

A potential new route to super-efficient carbon dioxide reduction: Catalyst offers 800-fold boost

One of the most promising strategies being investigated to mitigate emissions of carbon dioxide (CO2)—a byproduct of electricity and heat production, transportation, and other industries—is the process of electrochemical reduction.

In this approach, electrical energy is used to convert recaptured CO2 into useable products and fuels, such as methanol and ethanol. But a challenge has been finding a catalyst that is efficient and fast enough to be practically used.

Motivated by this goal, a group of researchers led by scientists from the U.S. Department of Energy's (DOE) Brookhaven National Laboratory has identified an approach that can improve the speed of catalysis by a factor of 800.

The work, a collaboration between Brookhaven, Yale University, and the University of North Carolina at Chapel Hill, is published in the August 27, 2024 online edition of the Journal of the American Chemical Society.

"There are many materials that are able to catalyze carbon dioxide reduction, but you often need to apply a large amount of energy to the system, which is an economic constraint against large-scale deployment," said Brookhaven chemist Gerald Manbeck, one of the scientists involved in the work.

"The catalyst we studied requires far less energy and displays excellent performance. It may inspire the design of better future catalysts."

Manbeck and the research group—which included Brookhaven chemists Laura Rotundo, Shahbaz Ahmad (now a postdoctoral researcher at the University of Manchester in the U.K.), Chiara Cappuccino, David Grills, and Mehmed Ertem—started with an existing catalyst based on the metal rhenium.

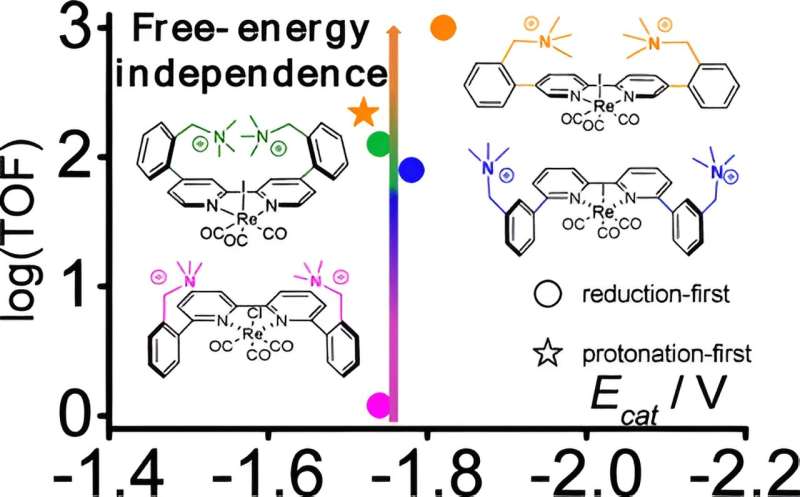

A rhenium atom forms the catalytic center of the molecule and is supported by organic fragments of carbon, nitrogen, oxygen, and hydrogen. The group created three new versions of the catalyst by strategically "decorating" it with positively charged molecules, or cations, with each version having a different distance between the cations and the rhenium metal center.

The group found that this spacing can significantly impact the effectiveness of the catalyst. At a key distance, the rate of catalytic activity skyrocketed, increasing by a factor of about 800—critically, without the need for much additional electrical energy.

The group learned, via the aid of computational chemistry, that the cations have a stabilizing effect on later parts of the catalytic reaction, and the fastest catalyst unlocks a low-energy pathway that is not typically observed for rhenium-based molecular catalysts.

This discovery was achieved using computational resources of the Center for Functional Nanomaterials, a DOE Office of Science user facility located at Brookhaven Lab, as well as Brookhaven's Scientific Data and Computing Center.

"This basic catalytic framework is well known in the research community, and while there have been many efforts to tailor its catalytic properties, our findings really highlight the substantial rate increase that can be achieved through a subtle geometric change in the organic scaffold," said Rotundo, the paper's lead author.

The researchers uncovered these findings using several methods. These included cyclic voltammetry, an electrochemical technique that can measure the energy characteristics and rates of the reaction, and infrared spectroelectrochemistry, which provides information on the structural changes that occur in the reaction participants.

To execute this technique, the group used a novel apparatus that some of the members had developed, which they described in a paper published last year. The apparatus is uniquely sensitive to observing chemical changes very close to the interface between a solution—where the catalytic reaction takes place—and the surface of the electrode that supplies the electrical energy.

In future work, the researchers plan to elaborate on their catalytic system by integrating light absorbers based on semiconductors, such as silicon, which are materials that capture incoming light and convert it to electrical energy.

They will be looking to see if the light absorbers can provide enough energy to partially drive the catalytic reaction, reducing the amount of direct electrical energy needed.

This investigation will directly align with the mission of CHASE, which aims to develop photoelectrodes that will capture sunlight and use that energy to drive the conversion of CO2 and water into liquid fuels.

More information: Laura Rotundo et al, Fast Catalysis at Low Overpotential: Designing Efficient Dicationic Re(bpy2+)(CO)3I Electrocatalysts for CO2 Reduction, Journal of the American Chemical Society (2024). DOI: 10.1021/jacs.4c08084

Journal information: Journal of the American Chemical Society

Provided by Brookhaven National Laboratory